Introduction to Chip LED: What is an LED Chip?

A light-emitting diode (LED) is a semiconductor device producing light. When the electrons carry the current flow through the LEDs, the light is emitted. The performance and energy efficiency of LEDs are better than other light sources with no doubts. When it comes to LEDs, LED chips must be mentioned, which are the most important semiconductor components of LED displays.

What are LED Chips?

The chip LED is the core component of the LED light sources. LED chips are panels made up of semiconductor layers. The illumination can be emitted by allowing electrical currents to pass through the chip LED. Although the chip LEDs are usually small, they can create bright, intense light images.

How Does a Chip LED Work?

When chips of LEDs are connected to a source of power, the protons and electrons will flow through the LED chips. Unlike incandescent bulbs using filaments to burn out, every LED will be illuminated only by the movement of electrons. Hence, chip LEDs will not be hot and consume less electricity when lighted up.

What are the Differences between DIP LED, SMD LED, and COB LED?

Due to the different technology of LED chip packages, LEDs are commonly categorized into DIP LED, SMD LED, and COB LED.

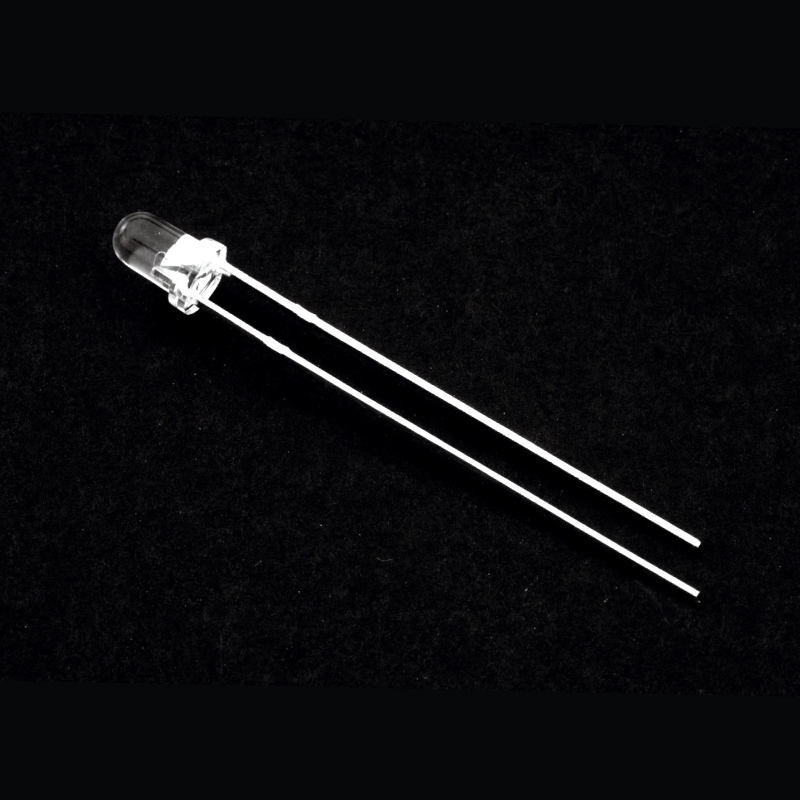

DIP LED

Dual-In-Line Package LEDs (DIP LEDs) are LEDs of two straight parallel connecting pins. Oasistek’s DIP LEDs contain visible and invisible lights and DIPLEDs are available in various features, sizes, colors and angles, like 3mm, 5mm, square, round, concave DIP LED.

(Figure 1: DIP LED)

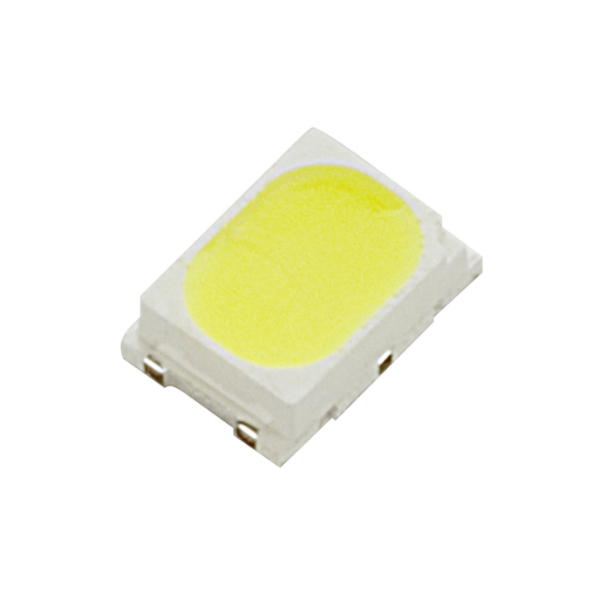

SMD LED

A surface mounted device LED (SMD LED) is LED mounted on the printed circuit boards by the manner of surface-mount technology (SMT). Thanks to SMT technology, SMD LEDs are mounted without using any wires and have more versatility and complicity of designs.

SMD LEDs are solid-state semiconductor devices converting electricity into light directly. The core of SMD LEDs is semiconductor chips fixed on the bracket .The whole LED chips are packaged with epoxy resin or silicone. One end of the chip LED is the negative electrode, and the other end is connected to the positive electrode of the power supply.

(Figure 2: SMD LED)

COB LED

The chip on board LED(COB LED) comes as a high-powered chip LED which is wired on PCBs with optimal thermal management. COB LEDs are more likely to utilize every little space well after packaging, since there is no need for electroplating and reflow soldering.

(Figure 3: COB LED)

DIP LEDs are the most traditional LED lights and are widely used. However, DIP LEDs are less energy-efficient and produce less lumens per LED compared to other LED chips.

On the other hand, COB LED is the latest technology of LED chips. Among three LED chips, a COB LED allows the highest packing density. The technology of COB LEDs enables the development of high-power diodes with a small light-emitting surface area. Therefore, the COB LEDs may optimize the efficiency of illumination.

However, the limitation of COB technology is that the power rating of the luminaire needs to be installed. SMD LEDs are preferred in high power applications due to higher reliability than COB LEDs. In addition, SMD LEDs can be used in color changing light bulbs, while COB LEDs cannot. Hence, SMD LEDs still have a wider range of uses compared to COB LEDs.

What are the Features of Chip LEDs?

LED chips are known for superior performance compared to other traditional light sources. Chip LEDs can produce light with higher energy efficiency.

Besides, stability and reliability are also two main advantages of chip LEDs. When turning on the LED chips, almost zero heat will be produced. The LED chips and the LED displays are cool to touch even when they are lit up. Thus, chip LEDs might increase safety and reduce the possibility of accidents because of not producing heat.

Last but not least, durability is also a feature of chip LEDs. LED chips may have longer life spans than incandescent light bulbs in common situations.

What are the Applications of Chip LEDs?

The technology of LEDs is constantly evolving. The brightness of the light produced by chip LEDs is significantly better than before, and LED chips have the capacity to change colors. Nowadays, there are more advanced LED chips that are designed for home, commercial, and industrial use.

For example, some of the LED chips are made small in order to be used in tiny smart appliances and high end electronics, such as laptop computers, mobile phones, and indicator lights. Chip LEDs are also used in LED lightings and light bars outdoors.

What are the Advantages of Choosing Oasistek?

Taiwan Oasis Technology Co., Ltd. (Oasistek) has been dedicated to the production and development of Light-Emitting Diodes (LED) and semiconductor components for more than 48 years. Oasistek provides semiconductor products and services with a complete and scientific quality control system. Our mission is to fulfill our clients’ needs in every aspect.

It is necessary to choose the most appropriate product according to types, colors, sizes, brightness and digital symbols of the LED sources. Here are several advantages of choosing Oasistek’s Chip LEDs:

- Integration of Manufacturing: Oasistek has a complete vertical integration of upstream to downstream. Moreover, the R&D team of Oasistek integrates optics, circuits, controls, and mechanisms to improve and control manufacturing quality of LED chips.

- Customization:The customization including adjusting colors of beam LED chips is available. Oasistek devotes our resources to meet different and specific needs and uses.

- Electronic Professional Manufacturing Service: Oasistek offers OEM service to various LED chips with innovative technology. We provide printing, assembly, testing and packaging of various electronic products with LED light sources.

- Worldwide Certification: Oasistek incorporates safety systems in every little step of the manufacturing process. Besides, we have global certification and experience to serve our clients in both domestic and international markets.

Oasistek has provided well-recognized LED chips and LED components to our clients. For more semiconductor product information, please be sure to contact Oasistek and submit your questions. We will reply to your messages as soon as possible.